In the rapidly evolving world of defense manufacturing, precision, reliability, and efficiency are non-negotiable. From the creation of aircraft components to sophisticated weaponry, the demand for flawless production is higher than ever. One technology that has revolutionized this field is CNC precision machining. This manufacturing process, which uses computer-controlled tools to shape materials with extraordinary accuracy, has become a cornerstone of modern defense production.

Enhancing Accuracy and Consistency

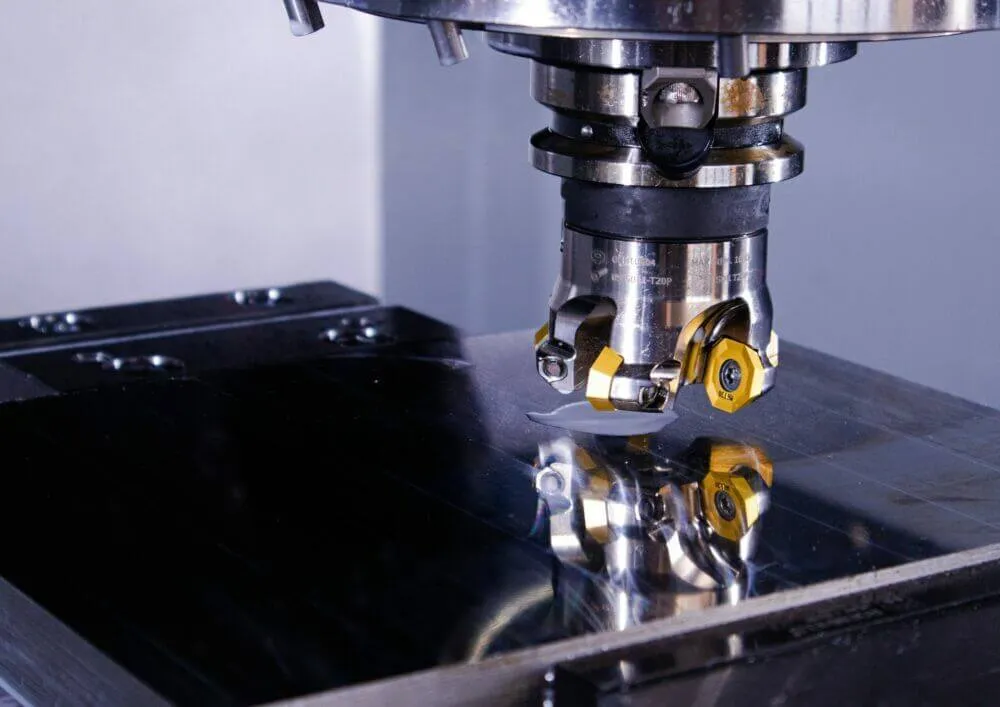

One of the most critical aspects of defense manufacturing is accuracy. Components used in military equipment must meet strict tolerances to function correctly and safely. CNC precision machining provides unparalleled accuracy, often down to microns, ensuring that each part is manufactured to exact specifications. Unlike manual machining, where human error can introduce variations, CNC machines follow programmed instructions with consistency. This level of precision is vital for defense applications, where even minor deviations can compromise safety or effectiveness.

Reducing Production Time

Speed is another significant advantage of CNC precision machining in defense manufacturing. Traditional machining methods require extensive manual labor and time-consuming setups, slowing production rates. CNC machines automate many of these processes, reducing the time required to produce high-quality components. This efficiency is particularly crucial in defense manufacturing, where rapid production can be necessary to meet urgent demands or respond to evolving military needs.

Supporting Complex Designs

Modern defense equipment often incorporates highly complex components with intricate geometries. CNC precision machining allows manufacturers to produce these sophisticated parts with high accuracy. From multi-axis milling to advanced turning operations, CNC technology can handle designs that would be challenging or impossible to achieve with conventional methods. This capability enables the development of cutting-edge defense systems, including advanced aerospace structures, precision-guided munitions, and high-performance engines.

Improving Material Utilization

Materials used in defense manufacturing, such as aerospace-grade alloys and specialized composites, are often expensive and challenging to source. CNC precision machining optimizes material usage by minimizing waste. Advanced software integrated with CNC machines allows engineers to plan tool paths that reduce excess cutting, ensuring maximum efficiency. By conserving materials, manufacturers can lower production costs and make the most of limited resources, which is essential in a sector where both performance and cost-efficiency matter.

Enhancing Reliability and Safety

Reliability is non-negotiable in defense manufacturing. Equipment failure can have catastrophic consequences, from mission failure to endangering personnel. CNC precision machining contributes to reliability by producing parts that meet stringent quality standards. Additionally, CNC machines can integrate real-time monitoring and inspection systems, detecting defects during production and preventing flawed components from entering the supply chain. This quality control ensures that every part functions reliably under demanding conditions.

Enabling Prototyping and Innovation

Innovation is a key driver in defense technology, and CNC precision machining plays a vital role in supporting research and development. Rapid prototyping using CNC machines allows engineers to test new designs quickly and efficiently. They can iterate on complex parts, validate performance, and refine designs before committing to large-scale production. This agility accelerates the development of next-generation defense systems, from unmanned vehicles to advanced radar components, helping military organizations maintain a technological edge.

Cost-Effectiveness in the Long Term

While the initial investment in CNC precision machining equipment can be substantial, the long-term benefits make it cost-effective for defense manufacturers. Reduced labor costs, minimized material waste, and higher production speeds contribute to significant savings over time. Additionally, the consistent quality of CNC-machined parts reduces the need for rework and maintenance, further lowering costs. In an industry where precision and reliability are paramount, these efficiencies justify the investment.

Supporting Global Defense Standards

Defense manufacturing operates under strict regulatory frameworks and international standards. CNC precision machining helps manufacturers comply with these regulations by producing parts that consistently meet required specifications. Whether it’s aerospace, naval, or ground equipment, CNC-machined components can be produced to align with ISO certifications and military standards. Compliance ensures that defense systems are interoperable, safe, and effective across different operational contexts.

Flexibility Across Defense Applications

CNC precision machining is versatile, serving various sectors within the defense industry. It is used in aerospace manufacturing for aircraft frames and engine components, in naval engineering for submarine and ship parts, and in ground defense systems for armored vehicles and weaponry. Its adaptability allows manufacturers to standardize production processes while accommodating the specific requirements of each application. This flexibility is crucial in an industry that demands both specialization and scalability.

Future Trends and Technological Integration

The role of CNC precision machining in defense manufacturing continues to evolve with technological advancements. Integration with additive manufacturing, robotics, and artificial intelligence is expanding the capabilities of CNC systems. AI-driven predictive maintenance, advanced simulation software, and hybrid manufacturing techniques enhance precision, reduce downtime, and enable more complex designs. As defense technology advances, CNC precision machining will remain at the forefront, supporting innovation and maintaining operational superiority.

Conclusion

CNC precision machining has become indispensable in modern defense manufacturing. Its ability to deliver high accuracy, reduce production time, support complex designs, and optimize material usage makes it a critical tool for the industry. Beyond efficiency and cost-effectiveness, CNC precision machining ensures reliability, safety, and compliance with stringent defense standards. As technology progresses, its integration with advanced manufacturing techniques will further enhance the capabilities of defense manufacturers. In a field where precision can mean the difference between success and failure, CNC precision machining is not just a manufacturing method—it is a strategic advantage.

CNC precision machining continues to transform defense manufacturing, enabling the creation of high-performance, reliable, and innovative systems that meet the exacting demands of modern military operations.